Optimizing Combustion in Thermal Power Plants: How Coal Flow Balancing Systems Drives Efficiency, Flexibility, and Low Emissions

Introduction

India generates nearly 80% of its electricity from coal, making thermal power plants the backbone of the energy sector. However, with the growing adoption of renewable energy, these plants face increasing pressure to operate more efficiently, flexibly, and sustainably. One of the most overlooked yet critical challenges is coal pipe flow imbalance, which leads to reduced boiler efficiency, higher emissions, and costly maintenance issues. The solution lies in coal flow balancing and combustion optimization systems, which not only improve efficiency but also ensure environmental compliance and long-term operational stability.

Understanding Coal Flow Imbalance

Coal pipe flow imbalance occurs when fuel is unevenly distributed to the burners. This imbalance creates zones of high and low combustion temperatures, leading to:

- Loss in boiler efficiency

- Increased NOx and CO emissions

- Higher levels of unburnt carbon in ash

- Frequent boiler tube and firing system failures

By achieving uniform coal distribution, plants can overcome these inefficiencies and ensure consistent combustion across all burners.

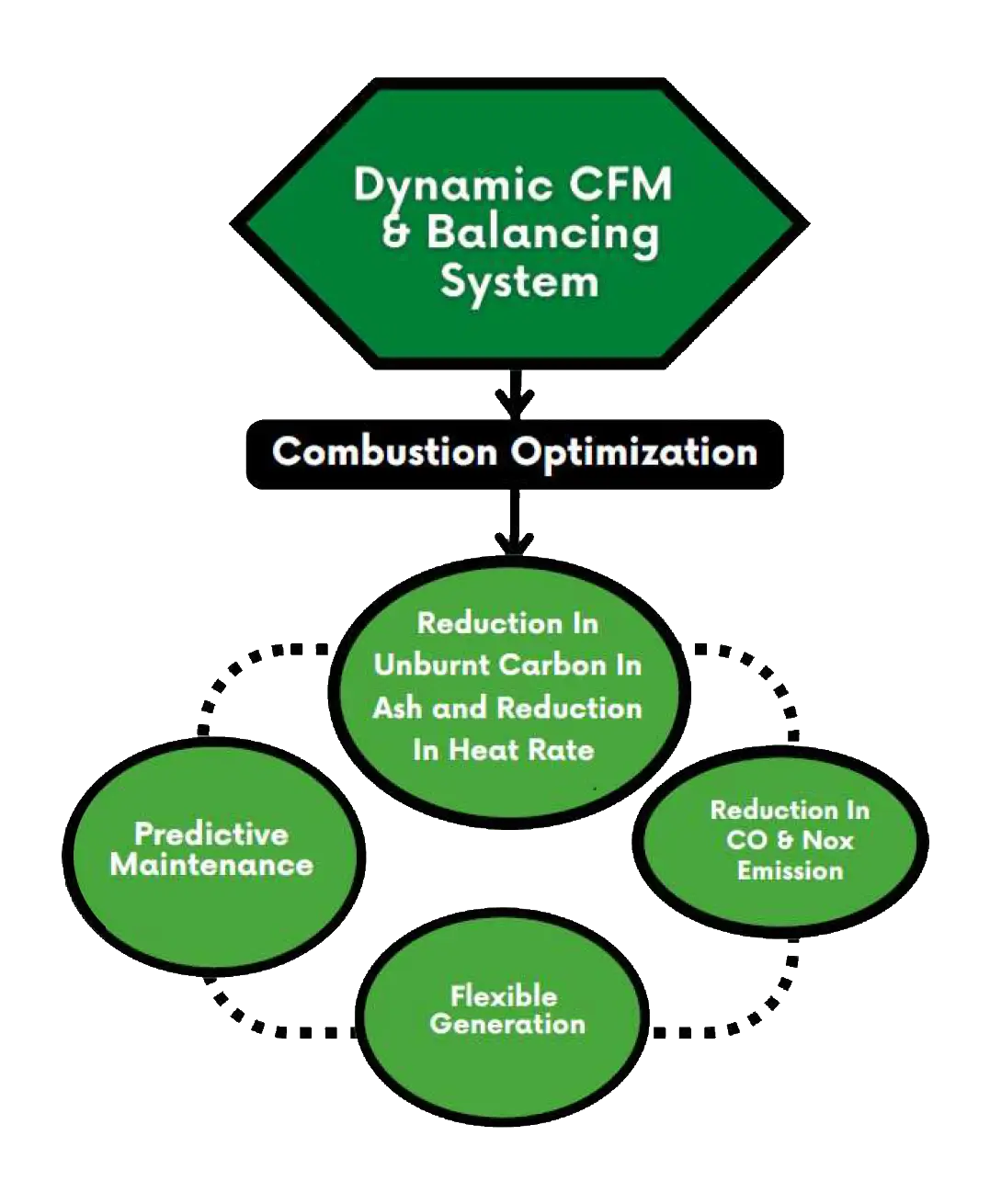

Advantages of Coal Flow Balancing Systems

- Improved Combustion Efficiency

- Reduces unburnt carbon in ash

- Optimizes heat rate for lower fuel costs

- Enhances flame stability across varying load conditions

Lower Emissions & Cleaner Power

- Reduction in NOx and CO emissions

- Better compliance with environmental regulations

- Supports India's Net Zero 2070 goals

Flexibility in Power Generation

- Enables thermal plants to handle rapid load changes

- Balances renewable fluctuations (solar and wind variability)

- Provides grid stability through flexible base-load operation

Predictive Maintenance & Reliability

- Continuous monitoring highlights imbalance issues early

- Prevents costly breakdowns in boiler tubes and firing systems

- Extends equipment life, reducing long-term O&M costs