About Us

Evolve is about making energy cleaner and smarter. Evolve helps industries use coal smarter through advanced technology, which reduces pollution. It should keep industry operating efficiently, reduce contaminant outputs, and protect the environment.

Evolve's primary focus is thermal power plants. For thermal power plants, we help them to monitor and adjust the fuel and combustion processes within their plant, allowing them to save fuel, reduce emissions and prepare to be more effective. The motivation for our team of engineers, data specialists, and energy professionals to develop a greener future is all about looking forward.

Our Vision

We envision clean, smart, and sustainable energy being used by the industry to create a better future for all.

Our Mission

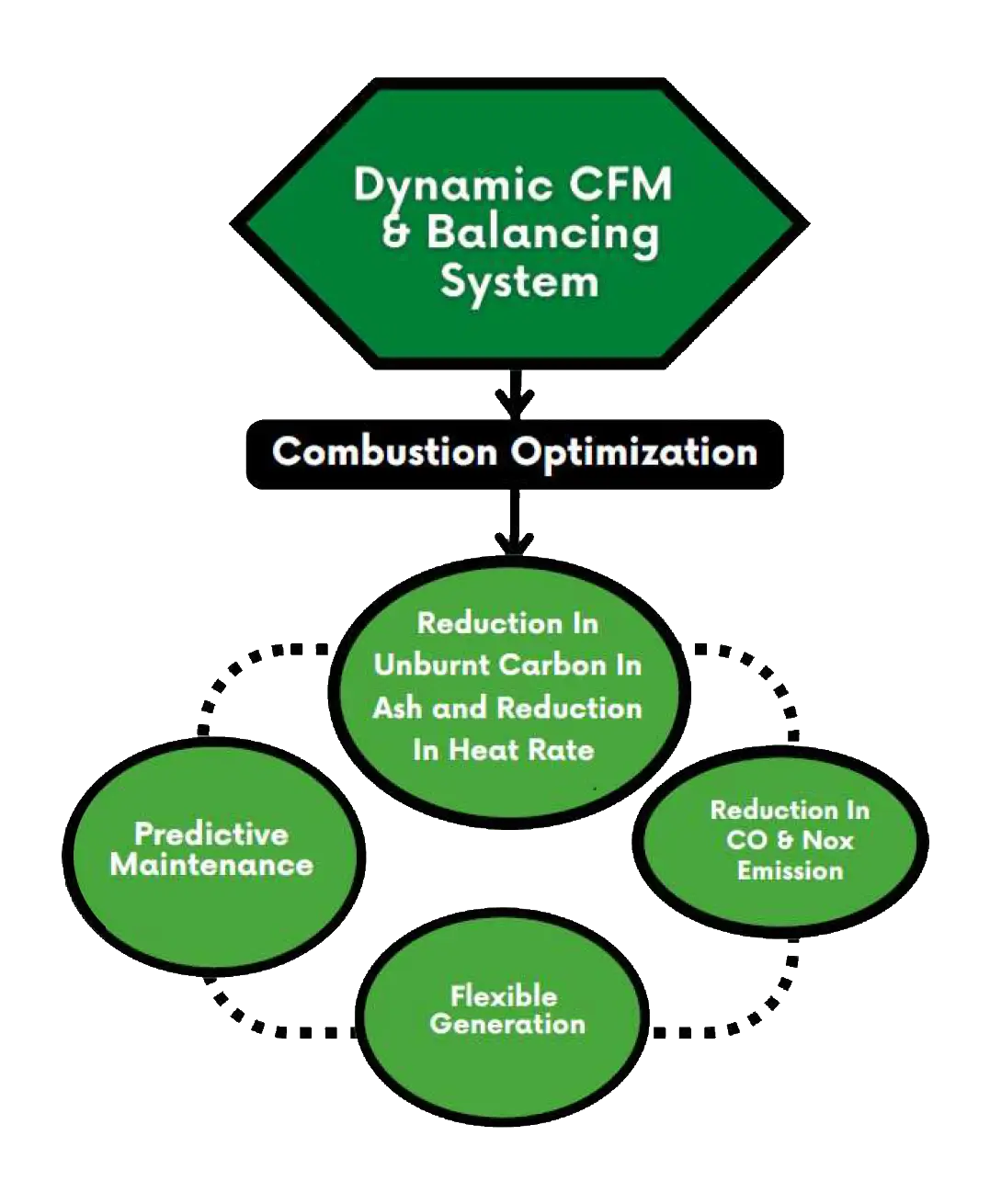

To provide Innovative technical solution that drive low carbon footprints by optimizing combustion in power plants by balancing coal flow and air to fuel ratio.

Our Values

• Integrity

• Excellence

• Innovation

• Sustainability

Navigating Towards Greener Future

Evolve Technologies has a goal to navigating towards greener future in Coal Combustion by reducing greenhouse gases through Dynamic Coal Flow Monitoring and Balancing System.

Energy security and CO2 emission reduction are two major concerns of today’s world. Improving efficiency of the energy systems is an essential option for the security of future energy and the reduction of CO2 emissions.

At COP26, in November, 2021, Prime Minister announced that India will achieve the target of net zero emissions by 2070. India’s 80% electricity generation is based on coal.

It is widely recognized within the electric utility industry that coal pipe flow imbalance is widely responsible for loss in boiler efficiency, higher NOx and CO emissions, increased unburned carbon in the ash, it is also responsible for increased combustion zone temperature resulting in boiler tube and firing system maintenance problems.

It has been considered as a potential area that needs to be addressed for improving unit performance. With the introduction of new generation ultra low- NOx burners, “uniform distribution of coal flow to the burners has become an important subject”.

Indian coal power utilities are undergoing a radical change with advent of renewable power generation. In order to ensure grid security and stability, the variability of solar & wind generation has to be taken care by flexible generation from thermal plants as base load.

Key challenges for a highly flexible power plant operation is reduction to the minimum load and the increase of the load change. This requires continuous monitoring of coal flow and adjustment of coal balancing for flame stability at low loads and complete combustion at high loads.

Why Choose Us?

Real-Time Monitoring

Capable of continuously measuring coal flow in real-time conditions using microwave-based sensors.

Accurate Coal Distribution

Ensures the mass, velocity, and temperature of coal in each pipe are within a permissible deviation of ±5%, for optimum combustion.

Emission Reduction

Combustion optimization results in NOx reduction, which is influenced by flame temperature and excess primary air velocity.

Predictive Maintenance

The system identifies flow imbalances, allowing early interventions and reduced maintenance costs.

Our Clients & Partners

We take pride in serving a diverse clientele across industries such as steel, mining, cement, power, and petrochemicals. Our cutting-edge ceramic and metallic flow solutions are trusted industry leaders for their durability, efficiency, and precision.